Guest article by Bridgeport Worldwide: FritsJurgens' new floor plate Flush

John DeRosa, one of our trusted partners in the USA from Bridgeport Worldwide, wrote a thorough and straightforward article about FritsJurgens’ new floor plate Flush. From thresholds and drop seals to the first ancient pivot stones – no floor plate subject is left untouched.

They’re here! Flush with the Floor Plates for Your System M/M+ Pivot Door

In today’s article, we’ll get into the details surrounding two new floor plate designs for the FritsJurgens System M/M+ pivot closer and their impact on sealing the pivot door and providing a no-threshold condition.

We will go over some of the challenges that our customers—OEMs big and small—face around specifying and building high-performance pivot doors and how FritsJurgens has been innovating to address them.

Listening sparks innovation

For many of our growing number of customers making pivot doors, the new flush-to-the-floor floorplates that FritsJurgens is launching this month are going to seem like a prayer answered.

The Dutch manufacturer, FritsJurgens, has launched substantial innovations and improvements to their line before. They make pivot hinge systems. That’s it.

This focus allows them to go deep into every detail of the technology, refine it, and deliver a product that continues to impress by responding to what our market is demanding. That goes from how the screws are engineered all the way down to the packaging, which we’ve heard has turned into something of a theatrical event on some job sites.

Since introducing their in-the-door pivot hinge systems to North America, the Bridgeport Worldwide team has been part of a continuous industry-wide conversation with door makers of all stripes who’ve had their world turned upside-down.

Flipping the heavy-duty closer from in-the-floor to in-the-door, FritsJurgens made delivering bigger and heavier pivot doors much easier and cost-effective for them. But the pivot door opening is a complicated beast, and once they realized the potential of this new hinge technology, they were ready to tie down the other parts of the monster.

“Wow, mind-blowing pivot hinge! Now, how about…”

It’s always gratifying to hear the ‘aha’ from someone just discovering the System M or M+. The simple shift in their thinking happens immediately after realizing they no longer need to deal with digging into the floor to accommodate a traditional bucket closer.

Then the conversation quickly moves to questions around sealing the pivot door. High-performance automatic door seals have moved from the commercial hardware projects and the occasional residential mechanical room, to pretty much everywhere in a project, we’re seeing our OEMs integrating these automatic door seals across all of their interior and exterior offerings.

However, pivot doors have been a particularly tricky challenge when you want to move away from brush seals and silicone flipper seals to something more robust.

Look, ma, no threshold!

The architectural trend of blending the outside world with the interior space has grown along with developments in door technology and goes beyond just making bigger openings. The no-threshold condition between the interior and exterior has become the new gotta-have-it move when it comes to any opening, especially pivot entrances. This trend has also been driven by an increased call for ADA compliance and other universal design and accessibility principles.

Better sealing solutions for pivot doors

Design intentions are lovely, but a successful zero-threshold condition requires applying drop seal technology to properly seal the opening, keeping the weather out and the energy efficiency standards high.

Sealing the top and bottom of the pivot entry door for driving rain and climate, or the interior pivot door for sound and light, are important roles for the pivot door, but it has always been a challenge to achieve a good seal. Now, with the introduction of the new System M/M+ floor plate Flush, getting the perfect seal at the top and bottom of your pivot door is possible.

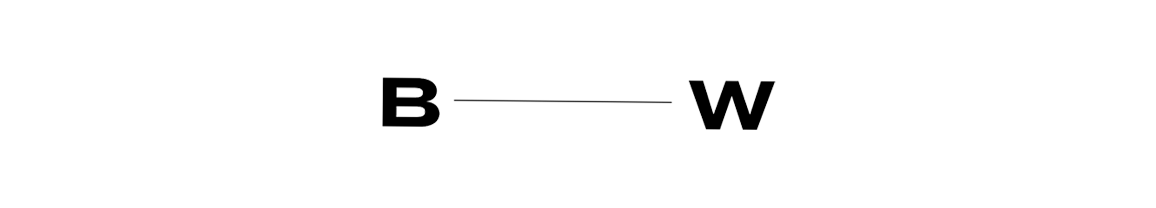

Technical drawing of the new floor plate Flush:

What the new plates provide:

Tighter gaps. The undercut is reduced to only 7 mm (~.28“)

No collisions. The round plinth that accepts the spindle is as wide as the closer body—32 mm

The rest of the plate can be set flush with the threshold material

The plate can be used with a standard 1/4“ high ADA aluminum door sill

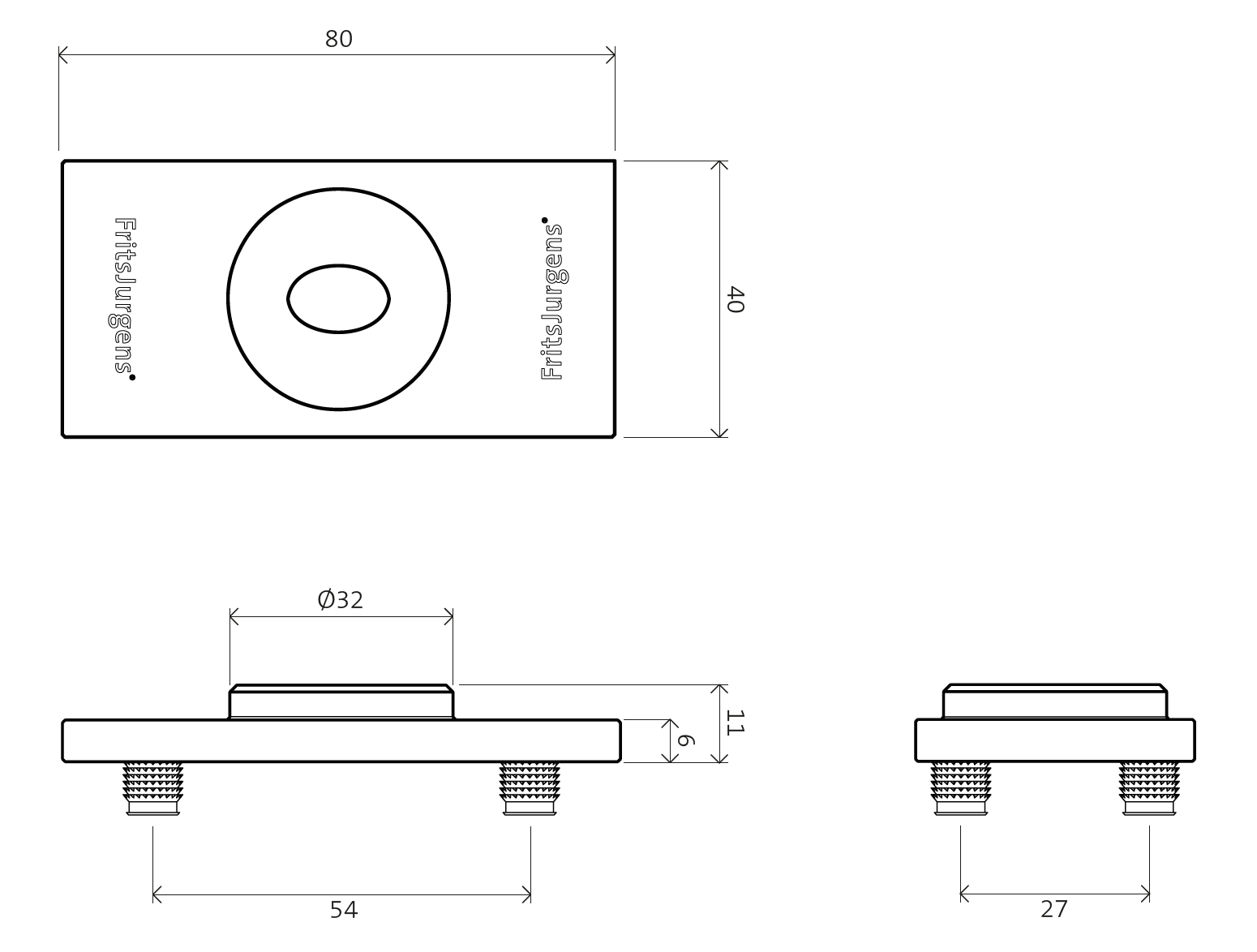

Below you see the original System M/M+ floor plate on the left and the new floor plate Flush on the right.

The new M/M+ floor plate Flush sits flush in the sill and can be used with any threshold scenario, including aluminum ADA sill, wood or stone thresholds, finished floors, concrete, tile, wood, and more. Because the floor plate is now perfectly flush, gasketing and drop seals can easily deploy without scraping up against the floor plate when actuated.

Bridgeport Worldwide has recently begun to offer the Athmer Schall-Ex L-15/30 WS Pivot door seal solution. It features an adjustable roller actuator, which helps negotiate the pivot door’s unique approach to the jamb. As shown above, it can work with either the 11 mm or 7 mm gap. Now, pivot door manufacturers can provide high-performance automatic seals at the threshold (and at the top, too!)

The push for larger pivot doors has also pushed for better-engineered slabs. Prior to this, to be able to incorporate high-performance drop seals, you would need to make your door at least 2-1/2“ (63,5 mm) thick. The new plates make it possible to run the Athmer door seal alongside your System M32+ and get it all into a minimum 2-1/4“ (57,15 mm) thick door.

We expect that the synergy between the performance of the System M+, automatic door seals, and these new flush plates will result in an enhanced level of performance for the entire pivot door opening.

But what about that 0° floor plate adjustment?

The standard floor plates have a handy way to adjust the 0° resting position of the floor plate.

As soon as we introduced the FritsJurgens System M to our market, we were having “the talk” with our door makers about their wanting to sink the floor plate into their threshold.

“Well, you’ll lose the floorplate adjustment,” we warned. A short pause, then, “That’s okay!”

Many of our best door makers are pre-hanging the whole frame, threshold, and door in their shops anyway, so a perfect fit is just a shop tweak away. Our entry door OEMs were telling us that with single-acting doors closing into a stop, especially when the System M+ arrived with its Latch Control, they did not really need that 0° adjustment to get a precision installation.

We do still see this adjustment being useful for sets of doors, especially space partitions where you’d want them to align perfectly when closed. The original floor plate still makes sense for installations of your doors directly on existing floors.

What is series 420 stainless steel?

First, it’s about the strength. All of the FritsJurgens floor plates accept the pivot spindle and then distribute the weight to the floor. For this purpose, FritsJurgens uses Series 420 Stainless Steel for all of its floorplates.

If you don’t know, you might be thinking this is FritsJurgens’ spinal tap moment. The truth is they cranked it up to 11 a while ago. Their floor plates have always been made of this grade of hardened Stainless Steel. That tiny oval hole in the System M plate needs to withstand the pressure of a half-ton door swinging for generations to come (current cycle testing is over 1 million). Series 420 hardened as it is in these floor plates is almost three times the hardness of Series 304 or 316 Stainless Steel.

Then, it’s about the corrosion. The plates have always provided superior corrosion resistance but, as the flush floor plates are now going to become one with the surface of an exterior threshold, FritsJurgens decided to turn up the volume on that too. They’ve been electropolished, removing all contaminants from the surface of the 420 Stainless Steel that could become vectors for corrosion. The thick chromium oxide skin that results provides an extremely corrosion-resistant surface and ready for whatever the world outside can throw at it.

You’ve come a long way, floor plate

It seems pivot doors have always been a challenge. In the Epic of Gilgamesh, written 4000 years ago, there’s a passage in which our hairy hero Enkidu is railing about a mighty pivot door made of cedar timbers. According to the text, the pivot door was about 22ft wide x 117ft high x 19 in thick (converted from cubits). Apparently, it’s a tough install. Even then, the basic components we know today were called out–door post, post cap, and pivot stone.

It likely looked something like this, but perhaps more impressive…

And the pivot stone looked like this…

Then came the revolution…

And now we have this revelation:

Okay, it may not change the course of history

But FritsJurgens has taken up the mission of bringing pivot door technology into the 21st century and beyond.

This latest product enhancement of the floor plate Flush will not be their last. FritsJurgens and Bridgeport Worldwide both rely on builders, makers, and installers of pivot doors to tell us about their experiences with these products and everything to do with delivering great pivot doors. Please keep the comments and suggestions coming. We’re listening.

– John DeRosa

Bridgeport Worldwide